Fuel Cells

Introduction

As the world continues to face the challenge of climate change, the need for sustainable energy sources has become more critical than ever. Fuel cells have emerged as a promising technology and a crucial component to provide clean, efficient, and reliable energy. resolvent believes in the power of modelling and simulation to further optimize fuel cells, using COMSOL Multiphysics, data analysis tools and reduced order models.

The Benefits of Fuel Cells

Fuel cells are electrochemical devices that convert chemical energy into electrical energy with high efficiency, ranging from 40% to 60%, compared to the traditional 30% efficiency of combustion-based power generation. They emit only water and heat as by-products, making them environmentally friendly. Here are some ways in which fuel cells can help in the green transition:

- Enhancing energy efficiency: Certain types of fuel cells can achieve efficiencies of up to 60% or more, making them very effective energy sources.

- Providing reliable power: Fuel cells are a great option for backup power in sensitive infrastructure and PtX applications since they can deliver dependable and uninterrupted power.

- Supporting transportation electrification: Fuel cell electric vehicles (FCEV) use a propulsion system similar to that of electric vehicles, where energy stored as hydrogen is converted to electricity by the fuel cell. This is part of the solutions for eco-friendly transportation methods and lower carbon emissions.

How resolvent Can Help with Modelling and Simulation of fuel cells

Modelling and simulation can play a crucial role in accelerating the green transition by optimizing the design and performance of fuel cell systems. Here are some examples of areas where modelling provides crucial insights:

- To optimize the fuel cell, in depth understanding of the electrochemical processes is needed: Here modelling can provide insights to the electrochemical processes that occur within the fuel cell, such as the reactions at the anode and cathode, ion transport, and current flow. This understanding can help identify the limiting factors and inefficiencies in the fuel cell.

- Evaluating design parameters: Based on validated models the impact of design parameters on the performance of the fuel cell, such as the size and shape of the electrodes, the thickness of the membrane, and the flow rate of the reactants can be tested. By simulating the performance of different designs, it is possible to identify the optimal design for a given set of operating conditions.

- Predicting performance: Performance prediction of the fuel cell under various operating conditions, such as changes in temperature, pressure, and reactant concentrations. This can help identify the optimal operating conditions for the fuel cell and guide the design of control systems that can maintain those conditions.

- Optimizing the control strategy: Optimizing the control strategy for the fuel cell, is crucial for maintaining optimal performance. By simulating the response of the fuel cell to different control inputs, it is possible to identify the optimal control strategy that can maximize the efficiency and lifespan of the fuel cell.

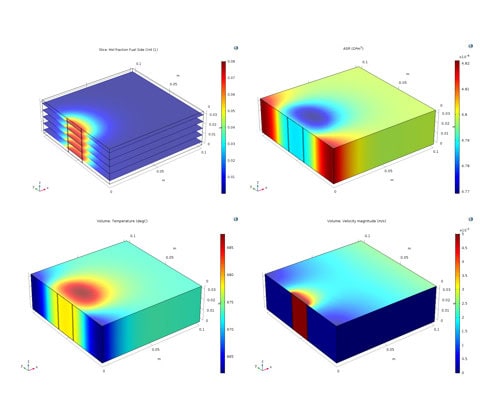

Box Model Application

In resolvent we have developed a so-called “box model”, which is a single-layer model, that can scale to a multilayer stack model. The model includes the following physics:

- Chemistry for the air and fuel sides

- Flow for the air and fuel sides

- Transport of species for the air and fuel sides

- Heat transfer

- Electrical current

The model parameters such as material properties, geometries, and kinetics are generic and can be turned for any specific cell material or stack design. Other parameters, such as gas transport properties and thermodynamics originate from available public literature.

One of the strengths of the box model is its ability to produce a wide range of results, including air and fuel velocities, pressure, temperature, current density, and gas composition. By analyzing these variables, engineers can identify areas where improvements can be made to enhance fuel cell efficiency and reduce costs.

Furthermore, the box model can be used to investigate the effects of different operating conditions on fuel cell performance, such as changes in temperature, pressure, or gas composition. This can help engineers optimize fuel cell performance under a variety of real-world scenarios.

The model mesh will have only a single element on the vertical axis and a mesh, which will ensure a suitable trade-off between accuracy and computational time. The model will be configured with a suitable solver for this type of Multiphysics problem.

The model will be able to produce the following plots of results (2D, top-view): air velocity, fuel velocity, air pressure, fuel pressure, temperature, current density, mol. fraction of fuel species, mol. fraction of O2, ASR, Reforming rate, H2-Consumption, fraction of fuel species, mol. fraction of 02, ASR, Reforming rate, H2-Consumption, Water-gas-shift rate, Over potential, Heat generation. The model will generate a table report with the most important calculated variables, as shown in the following tables.

Conclusion

The green transition is a critical task that requires the collective effort of individuals, businesses, and governments worldwide. Fuel cells have the potential to play a significant role in this transition by providing a clean, efficient, and reliable source of energy. We at resolvent can help with Modelling and simulation which can help accelerate this transition by optimizing the design and performance of fuel cell systems, reducing costs, and improving their reliability. With the urgent need to address climate change, now is the time to embrace sustainable energy sources and move towards a greener future.