Challenge and Ambition

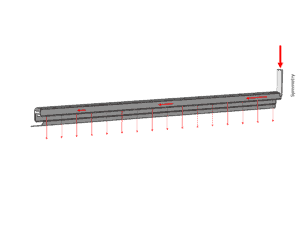

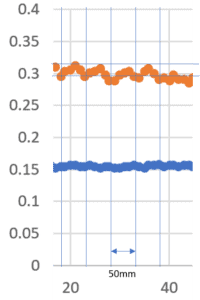

Alfa Laval were facing problems distributing a thin film of a non-newtonian fluid evenly through the narrow slot of the die-coater when changing to a fluid of considerably higher viscosity. Due to the unintuitive pattern of the maldistribution of the fluid many candidates were suggested as the main cause of the problem by the knowledgeable and experienced Alpha Laval production and development staff. These candidates became the starting point for doing virtual trouble shooting, while production was still running.

Solution

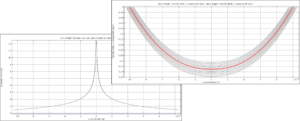

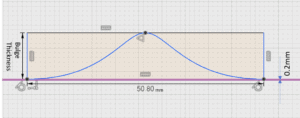

A full CFD- analysis was performed on the distributer and the suggested causes was analyzed one after the other. A sensitivity study was performed which pointed at a very small variation in the slot width was, by far, the most significant factor. Combining this knowledge with the fact of the significantly higher pressure state of the fluid pointed to deflection of distributer slot itself. The mal distribution was now realized to follow the deflection pattern of the distributer. A stiffening of the slot was now shown to be needed

Customer: Alfa Laval

Industry: Process (Filtration)