Client: Topsoe

Value created:

Based on the simulations and analysis carried out by simulation specialists at Resolvent, it was possible to reduce the weight of the tube sheet from 19.7 Tons to 14.9 Tons (24% reduction). Resulting in several benefits such as reduced cost, easier transportation, etc.

Description:

By utilizing nonlinear FEA, which allows for higher fidelity modelling (geometry and physics) compared to the original design method, a reduction in the needed safety factor was achieved. The tube sheet was demonstrated to be safe against several failure modes.

Mech. Manager: “We value the seamless high-quality collaboration with resolvent – it is as being part of the same Topsoe family.”

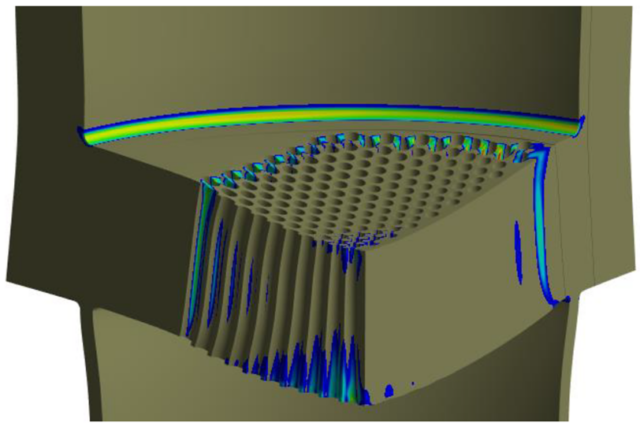

Plastic Strain

FEA plot of a 90-degree section of the tube sheet, channel, and shell showing the plastic strains. Demonstrating that the steam superheater, subjected to internal pressure, will not fail due to plastic collapse (rupture) according to ASME VIII-2.

The steam superheater was also demonstrated to be safe against thermal ratcheting (low cycle fatigue), local failure (crack initiation), and high cycle fatigue failure.