Aim

The primary objective of EEEHy (Economic and Efficient Electrolytic Hydrogen Production) was to generate comprehensive knowledge in areas such as materials, microstructures, production processes, as well as stack and system design, with the ultimate goal of developing a groundbreaking prototype for an electrolyzer based on high-temperature and pressure alkaline electrolysis cells.

The project received funding from Innovation Fund Denmark, Grand Solutions and the involved partners were:

• resolvent

• Technical University of Denmark, Department of Energy Conversion and Storage

• Danish Power Systems

• Haldor Topsoe A/S

• Sur-Tech A/S

• Aarhus University, Department of Management

• GreenHydrogen

• Sandvik Materials Technology

• FORCE technology

The technology enables the storage of surplus electricity from intermittent renewable energy sources like solar and wind, serving as a link between the electricity grid and sustainable fuel/chemical production. The project focuses on improving electrocatalysts, electrodes, and production scalability, with plans for technology development and commercialization. The goal is to raise the technology readiness level from 2 to 5, bringing this hydrogen-producing technology closer to a robust commercial product.

Challenge

One of the primary challenges in the development of electrolysis stacks that utilize ceramic membranes is to ensure their durability and stability for improved economic feasibility. Therefore, significant attention is devoted to addressing issues such as membrane degradation, seal integrity, and other factors that can impact the system’s overall efficiency. The failure of a membrane within a stack can lead to decreased stack efficiency and a reduced operational lifespan. As a result, it is crucial to consider not only the electrochemical performance but also the mechanical performance of electrolysis stacks incorporating ceramic membranes during their development.

Designing a stack with integrated ceramic membranes poses challenges due to the fragility of ceramics and the need to ensure structural support under cycling between operating and stop conditions.

How we helped

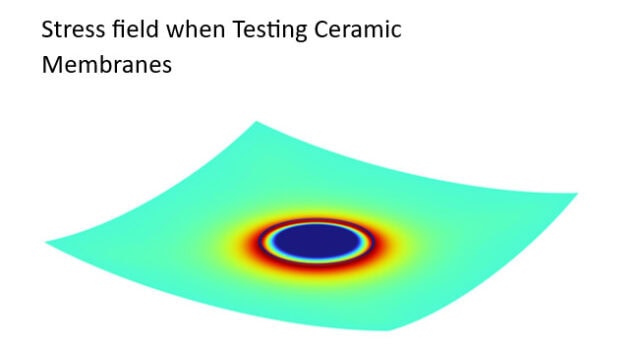

The main structural analysis was carried out on the ceramic membrane and polymer cell frame using Weibull theory and unit cell boundary conditions for FEM analysis:

The Weibull theory and ball-on-ring testing were used providing insights into its strength characteristics and failure behavior.

The efficient volume represents the volume of a uniaxially tensed specimen that has an equal probability of failure as the ball-on-ring specimen test. The concept of efficient volume allows for scaling up the results from small-scale laboratory testing to the geometry and stress field of a real-size cell.

In larger specimens, the probability of larger flaws or defects is higher, which can result in a lower apparent strength. Therefore, the strength of the ceramic membrane needs to be related to the size of the specimen used for testing. This scaling based on the size of the specimen allows for a more accurate estimation of the strength of the membrane under real-world conditions.

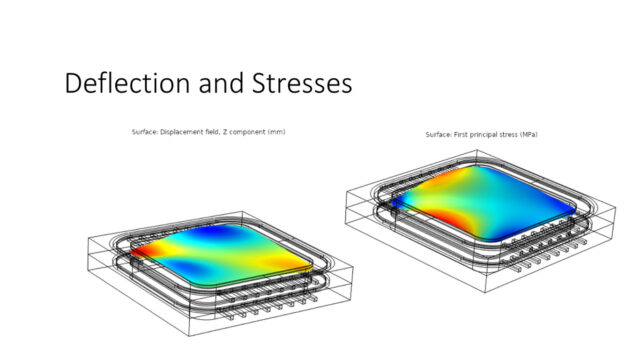

This approach combined with a unit cell FEM mechanical analysis was then used to evaluate the structural integrity of the stack membranes.

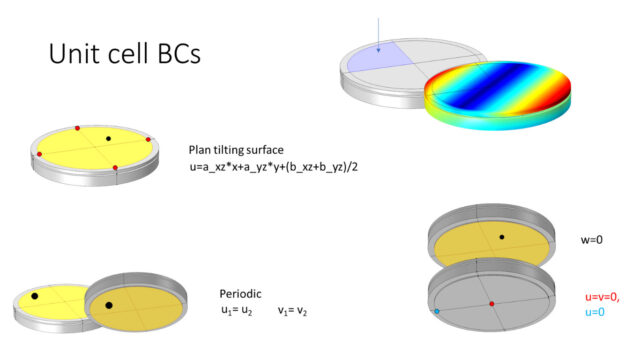

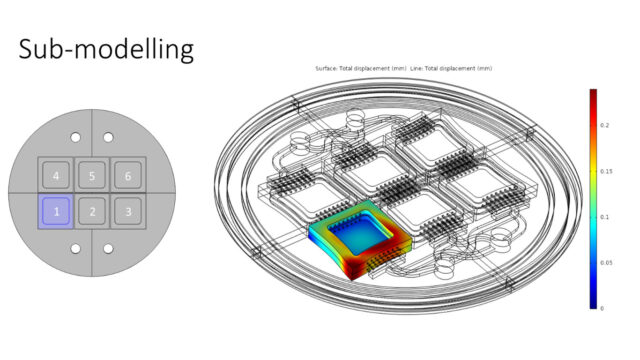

Unit cell boundary conditions simplify the analysis by reducing the complexity of the problem. By using unit cell boundary conditions, a representative cell can be modeled, rather than modeling the entire stack. This reduces the computational cost and allows for efficient analysis.

Benefit for the client

Testing stacks and understanding the failure mechanisms of ceramic membranes is difficult. However, if physical testing is combined with FEM analysis a virtual test rig can be realized, which is not only transparent but can also be changed for troubleshooting and design iterations at a much higher frequency. 3-5 variation of the design or BCs per day is common which is giving insight into the predominating mechanisms and effects at a much higher pace than physical testing alone. This supported product development leading to groundbreaking solutions for which patents are now applied.

Skills used

COMSOL® was used as the FEM simulation tool

• Weibull theory

• Unit cell BCs

• Sub-modelling

• Product development

Learnings

Making fragile ceramics structurally compliant for full electrolysis stacks heat cycles is a challenge. The thorough structural analysis combined with testing can create a strong basis for product development, understanding the failure mechanisms, and finding suitable solutions. This might seem like too simplified learning, but if you ever have tried to disassemble a stack with broken ceramic membranes and from this starting point try to understand the structural mechanism in play you would probably recognize the clear benefit of a simulation of the stack.

Industry

Power to X